First, the bender is actively controlled by the NC program, and in the course of work, manual intervention is generally not required, which eliminates the operator's artificial errors or errors;

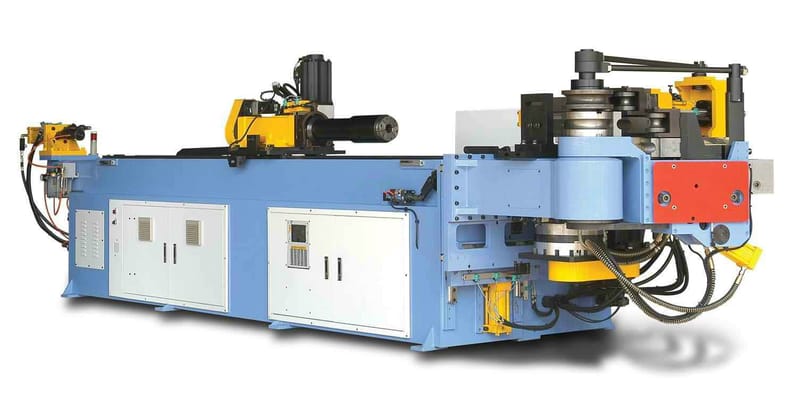

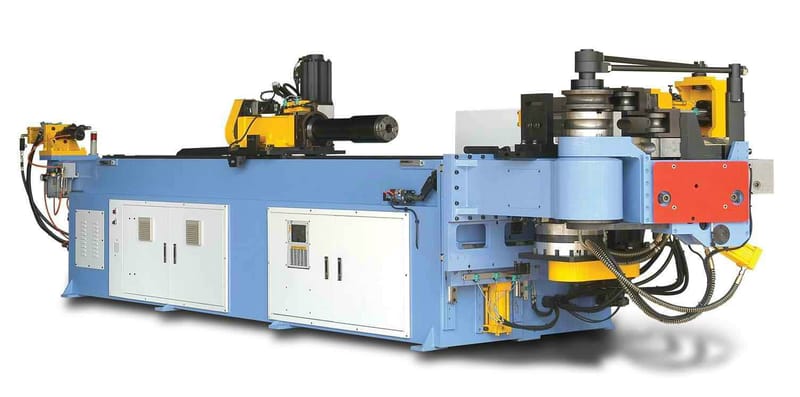

Secondly, the mechanical structure of the pipe bending machine is planned and produced according to the requirements of the precision machine tool. High-precision transmission components such as ball screw and tumbling guide are selected, and the rigidity, thermal stability and vibration resistance are good;

Third, the pulse equivalent or minimum setting unit of the servo drive system can reach 10 corps m to 0.5 Pm. At the same time, most of the work uses closed-loop or semi-closed loop control with detection reaction, with error correction or compensation function, which can be further Progressive accuracy and stability;

Fourth, the CNC machining center has a tool magazine and an active tool changer, which can complete the multi-faceted and multi-step machining of the workpiece after one clamping, and minimize the influence of the clamping error.

2. Flexible initiative, with a wide range of habits

Because of the selection of NC program control, the general-purpose tooling is used in the process. As long as the NC program is changed, the active processing of new parts can be completed. Therefore, it can be used to the requirements of continuous upgrading of products in the current market, and solve various varieties. And the issue of active production in medium and small batches.

3. Can complete the processing of complex parts

Because the pipe bending machine uses the computer interpolation and multi-coordinate linkage control skills, it can complete any trajectory movement and process any complex shape of the space surface, which can be conveniently completed such as propeller, steam turbine blade, car shape stamping die, etc. Processing of various complex surface parts.

4. High production efficiency

The pipe bending machine can reduce the maneuvering time and auxiliary time required for the processing of parts to the maximum limit, and significantly improve the production efficiency.

First, the feed motion and the main motion of the bender are stepless speed regulation, and the speed adjustment range is large. Therefore, each process can select the best cutting speed and feed speed;

Second, good structural rigidity and vibration resistance allow the machine to use large cutting amounts and strong cutting;

Thirdly, it is generally not necessary to stop the inspection of the workpiece, thereby effectively reducing the downtime in the machining of the machine tool;

Fourth, the moving parts of the machine tool adopt the active acceleration and deceleration method in the positioning, so the high idle motion speed can be selected, which greatly saves the auxiliary movement time;

Fifth, the machining center can choose the method of active tool change and active exchange workbench. The workpiece can be multi-faceted and multi-processed in one time, which greatly reduces the auxiliary moments such as workpiece clamping and tool setting.

Sixth, the processing steps can be gathered to reduce the turnover of parts, reduce the number of equipment and plant area, and bring great convenience to the dispatching of production.

5. Reduce labor intensity and improve working conditions

Because the operator of the pipe bending machine mainly uses the operation panel to operate the active machining of the machine tool, the labor intensity of the operator is greatly reduced, the production conditions are improved, and multiple machine tools can be easily handled by one person.

6. Conducive to modern production and handling

The pipe bending machine is used for processing, which can conveniently and accurately calculate the processing time of the parts or carry out active machining accounting, which can accurately calculate the production and processing costs, and is beneficial to the scientific processing of the production process. The pipe bending machine is the basis of advanced production systems such as computer aided planning and production, group control or distributed control, flexible production system, and integrated production system of accounting machine.