Products

Semi automatic pipe bending machine

DW38NCB China Semi automatic Pipe Bending Machine

Single Head Hydraulic Pipe Bending Machine use NC control, multiple sets of programs, multi-angle settings to make your operation and program settings more convenient.

DW50NCB Chinese Single Head Tube Bending Machine

Single Head Hydraulic Tube Bending Machine are widely used in mass production and processing of various types of stainless steel pipes, round and square tube bending molding, such as trolleys, exhaust pipe, wheelbarrow, headrest.

DW63NCB Single Head Steel Pipe Bending Machine

Single Head Chinese Hydraulic Pipe Bending Machine with NC Controlled, hydraulic driver and Presupposition various of bend angle for products.

DW75NCB Single Head Square Pipe Bending Machine

Single Head Hydraulic Pipe Bending Machine with Chinese and English Screen, Manual and semi-automatic modes can be selected for man-machine dialogue operation. Mobile pedal switch has two functions: start and stop.

DW89NCB Pipe Bending Machine from Chinese Factory

Single Head Hydraulic Pipe Bending Machine use high-performance hydraulic components, equipped with large capacity cooling system, effective control of working temperature.

DW114NC Hydraulic Large Pipe Bending Machine

Single Head Hydraulic Pipe Bending Machine use NC control, multiple sets of programs, multi-angle settings to make your operation and program settings more convenient.

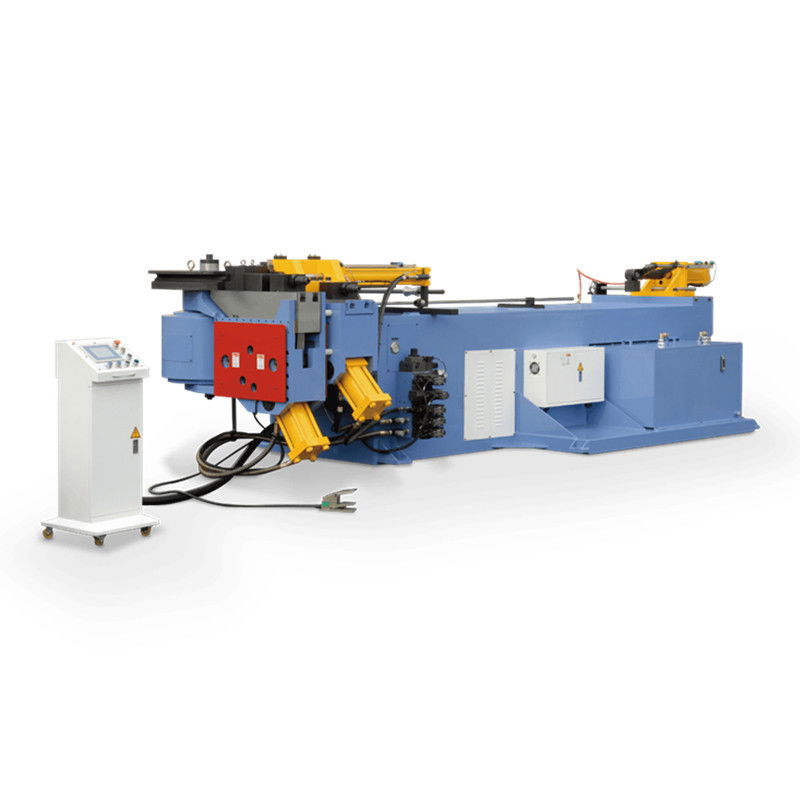

CNC Full automatic tube bending machine

DW38CNC Chinese Automatic Pipe Bending Machine

Electronic control system: It adopts Japanese Mitsubishi or Yaskawa servo control, which has strong performance and high stability.

DW50CNC Chinese CNC exhaust Pipe Bending Machine

All processing materials have touch-screen input, and MITSUBISHI super CPU can accommodate 400 sets of file editors. Each set of files can set 16 angles. Each elbow can be set compensation value and speed according to different material changes, and has the function of automatic detection of errors and faults.

DW63CNC Automatic Hydraulic Pipe Bending Machine

Each elbow of the same pipe can write 5 action sequences and 10 speeds separately. Touch screen supports both Chinese and English handover, and can be directly sent or clipped.

DW75CNC CNC Pipe Bending Machine for Car Headrest

The XYZ coordinates can be converted into YBC processing values. After editing, the key is protected to prevent any modification of the data. The electric control system is equipped with heat exchanger to automatically dissipate heat, which helps prolong the service life of the equipment.

DW89CNC Chinese Pipe Bending Machine Factory

The automatic oil filling system is installed on the machine, which can reduce the friction of the elbow, improve the service life of the mandrel and ensure the quality of the elbow.

Induction Heating Pipe Bending Machine

Heating Induction Pipe Bending Machine

1.All specifications can be made according to buyer's requirement . 2.The bending radius can be made according to buyer's requirements, maximum radius can achieve infinite. 3.The Lord oil cylinder of equipment is the standard configuration trip,it can be made according to buyer's request . 4, The data in the table is only for reference, the actual item is the standard.

Pipe Cutting Machine

Pneumatic Semiautomatic Pipe Cutting Machine

European-style high-strength machine head, high-efficiency worm provided, rotary engine drive, reaching high cutting potency, no noise or burrs. The machine head will flip for 45° on the left and right, angle is created clearly, that makes adjustment easier.

Hydraulic Semiautomatic Pipe Cutting Machine

European-style high-strength machine head, high-efficiency worm provided, rotary engine drive, reaching high cutting potency, no noise or burrs. The machine head will flip for 45° on the left and right, angle is created clearly, that makes adjustment easier.

CNC Automatic Pipe Cutting Machine

European-style high-strength machine head, high-efficiency worm provided, rotary engine drive, reaching high cutting potency, no noise or burrs.

Tube End Forming Machine

SG40NC Tube End Forming Shrink Machine

The product is controlled by microcomputer and driven hydraulically. It applies Chinese character display and man-machine conversation operation, and can be operated manually or semi-automatically. One-point foot switch has two functions, startup and emergency stop.

SG60NC Tube End Forming Shrink Machine

The product is controlled by microcomputer and driven hydraulically. It applies Chinese character display and man-machine conversation operation, and can be operated manually or semi-automatically. One-point foot switch has two functions, startup and emergency stop.

SG80NC Tube End Forming Shrink Machine

The product is controlled by microcomputer and driven hydraulically. It applies Chinese character display and man-machine conversation operation, and can be operated manually or semi-automatically. One-point foot switch has two functions, startup and emergency stop.