Induction Heating Pipe Bending Machine has automatic lubrication function inside the pipe

The Induction Heating Pipe Bending Machine has an automatic lubrication function in the pipe. The required bending lubricating oil is automatically injected into the pipe before each bending, which can improve the bending quality, increase the life of the mold, and simplify manual procedures.

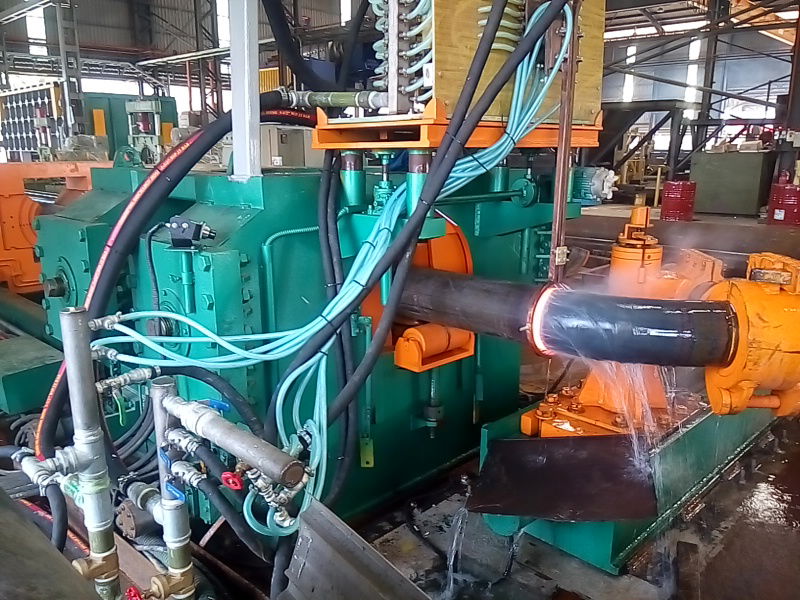

The Induction Heating Pipe Bending Machine has a standard guide mold auxiliary push device, and is designed with independent pressure and speed adjustment knobs, which can easily adjust the needs of pipe bending, which can make the normal thick and heavy, high-difficulty bending work easy. Such as bending of stainless steel pipes with smaller bending radius or bending of heavy pipes. The high-rigidity mechanical structure design and precision craftsmanship that conform to the principle of dynamic mechanics. With both structural strength, the simple crank and bending head design provides the largest bending space and minimizes the interference range of the machine. The structure is stable when bending, and relatively difficult bending work can be easily achieved, with high stability in use and long operating life.

Induction Heating Pipe Bending Machine material: stainless steel, pipe thickness: 3.5 (mm), radius of curvature: 101.6 (mm), model: A100TNCB, weight: 4500 (kg):, NC single-axis hydraulic automatic pipe bender, with PLC controller 10 kinds of bending angles can be edited and stored for automatic bending.

The intermediate frequency pipe bending mechanism adopts a joint-type locking design. Compared with the simple hydraulic cylinder push design, it can ensure a larger clamping force, and the bending quality is uniform and excellent. The Induction Heating Pipe Bending Machine has the function of slowly retracting the center. The retreat action time of the center penetration in the tube can be set according to the program, which can avoid the appearance of the tube raised by the fixed position of the penetration in the tube and improve the appearance quality of the tube.